2-way solenoid valves are available in a wide variety. They are electromechanically actuated, having two ports (inlet and outlet) and two switching planes (open or closed). They are generally normally closed so that they will close if there is a power outage and are used to start and stop gas or liquid flow. 2-way solenoid valves can be used for various tasks, such as isolation and shut-off, release, distribution, dosing, and mixing. Read More…

Solenoid Solutions manufacturers custom direct-acting 2 and 3-way solenoid valves and multi-valve manifolds for OEMs in the medical, appliance, transportation, power generation and industrial equipment markets.

Our solenoid valves are all tested in house following very strict quality guidelines. We opened our doors in 1936 and ever since then we have been committed to bringing top of the line products and customer service that cannot be beat!

Lexair, Inc. stands at the forefront of innovation in the realm of solenoid valves. We are driven by a shared commitment to delivering unparalleled solutions to our customers. Our journey is defined by a passion for precision and a relentless pursuit of excellence in every aspect of solenoid valve design and manufacturing.

At Texas Industrial Remcor, Inc., we understand that the success of any industrial process hinges on the reliability and efficiency of its components. Therefore, our solenoid valves are meticulously engineered to deliver unparalleled performance, ensuring seamless operation in even the most demanding environments. We take pride in the precision and durability of our valves, a result of our...

At Hansen Technologies, we take immense pride in our extensive line of solenoid valves, crafted with precision and innovation. With a rich legacy of engineering excellence, we stand as a beacon of reliability in the realm of fluid control solutions.

More 2 Way Solenoid Valve Manufacturers

How a 2-Way Solenoid Valve Works

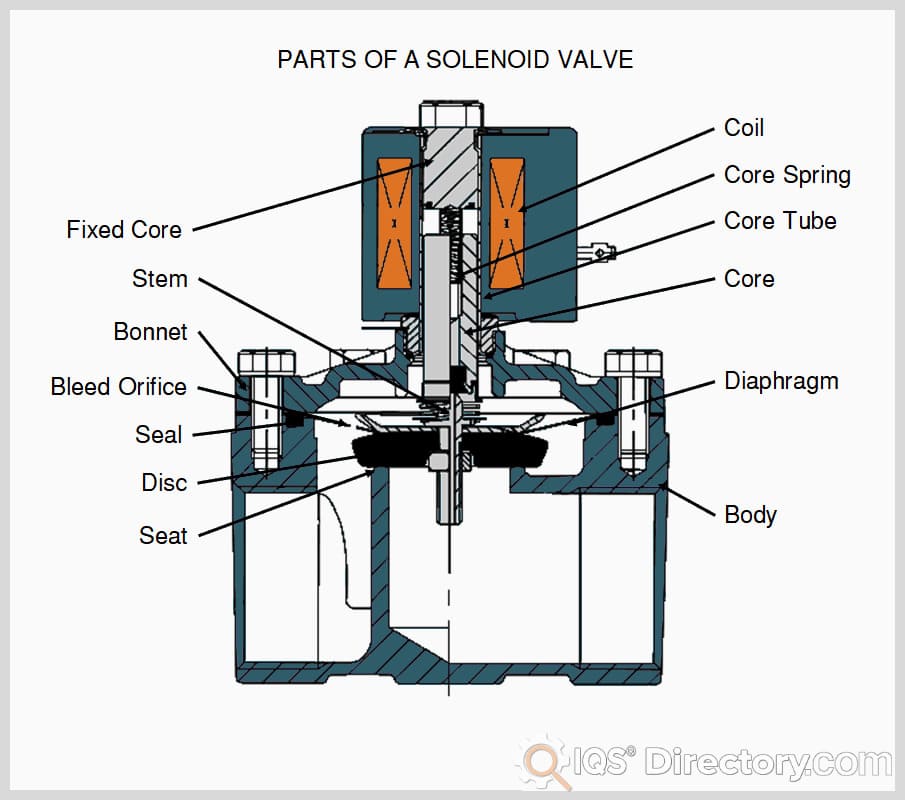

The flow of liquid or gas can be controlled with solenoid valves. Medical equipment has these valves built into it so it can be utilized effectively and safely. A solenoid valve opens or closes the valve using a plunger, enabling liquid to pass through or completely sealing it off without any leaks. This feature is a crucial step in the automation of fluid and gas control, and various solenoid valve types can do the same task in various ways. The normally closed solenoid valve is one tool for managing liquid or gas flow.

This valve functions in a manner comparable to other solenoid valves in that it either stops or starts the flow of the liquid, but it does it differently. The plunger is down in a usually closed solenoid valve when it is not energized, thereby sealing the valve and stopping the passage of liquid or gas. Once the normally closed solenoid valve has been powered on or energized, this opens the valve's seal and lets liquid or fluid flow through.

Types of Solenoid Valves

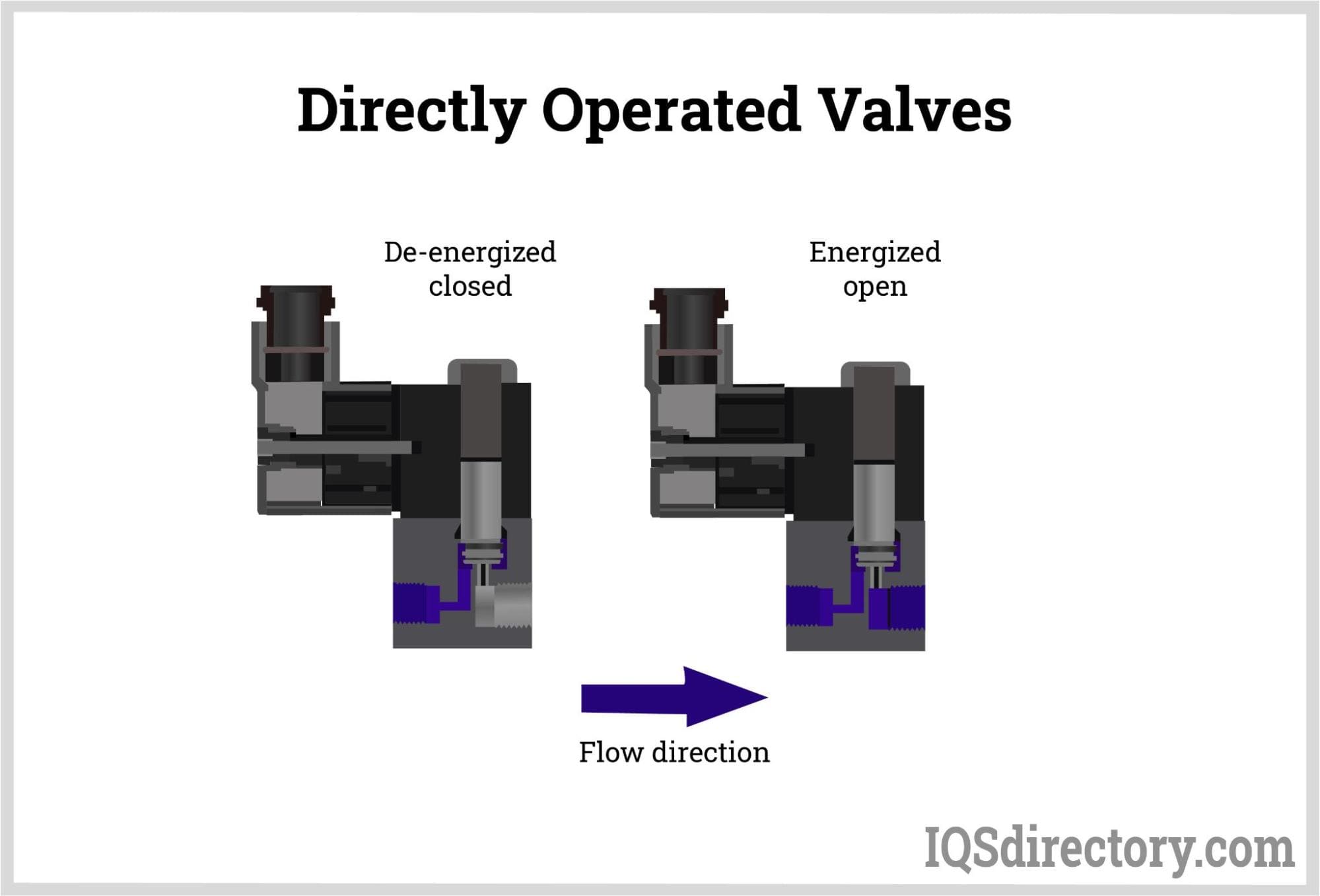

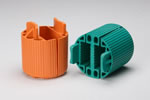

Directly Operated (Direct Acting) Solitary Valves

The most straightforward solenoid valves operate on a direct operated (direct acting) concept. A plunger with a rubber gasket on the bottom can block up the small aperture through which the medium flows. The plunger is held down to seal the valve by a little spring. First, a ferromagnetic substance is used to create the plunger. Next, a coil of electricity is wrapped around the plunger. A magnetic field is produced when the coil is electrically charged, pushing the plunger toward the coil's center. This process allows the medium to flow through by opening the aperture. A normally closed (NC) valve is what this is.

The converse is true with normally open (NO) valves, built differently so that the orifice is open even when the solenoid is not operated. The orifice will close after the solenoid is activated. The solenoid valve's orifice diameter and magnetic force are closely correlated with the maximum operating pressure and flow rate.

Indirectly Operated Solenoid Valves

Solenoid valves that are indirectly operated (also known as servo or pilot-operated) work by using the difference in pressure between the medium and the valve ports to open and close. These valves typically require a minimum pressure differential of approximately 0.5 bar. A diaphragm, or rubber membrane, separates the input and output.

A tiny hole in the membrane allows the medium to pass through and reach the higher compartment. The force and supporting spring above the membrane keep the valve closed. A narrow tube links the low-pressure port to the chamber above the membrane. A solenoid blocks this connection when it is in a closed state.

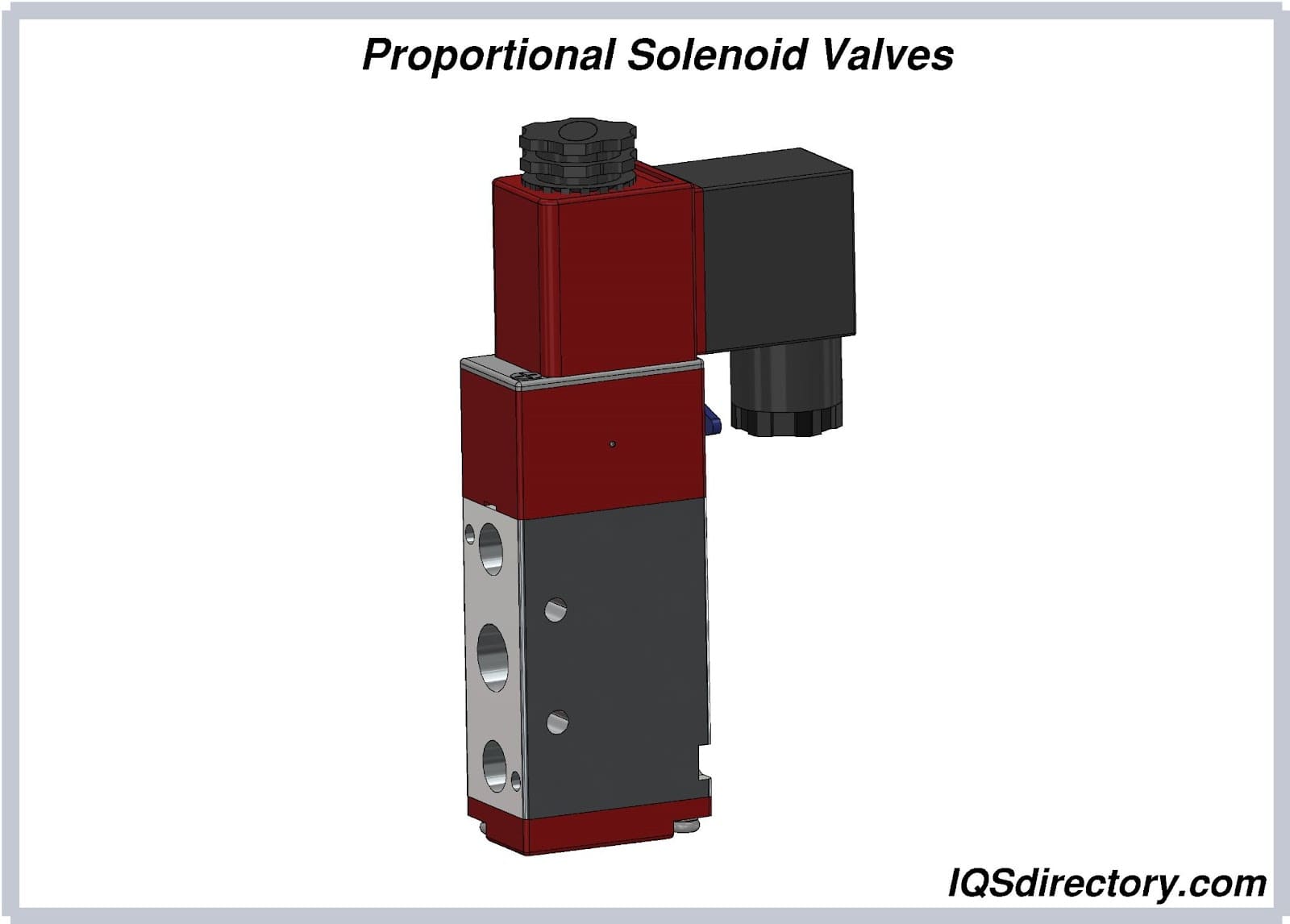

Semi-Directly Functioning Solenoid Valves

Solenoid valves that operate semi-directly combine the advantages of direct and indirect operation. Because of this, they can operate at zero bar while still being able to handle a high flow rate. They have a moveable membrane with tiny openings and pressure chambers on both sides, resembling indirect valves. However, the solenoid plunger's direct connection to the membrane marks a distinction. The membrane is directly lifted when the plunger is raised, opening the valve.

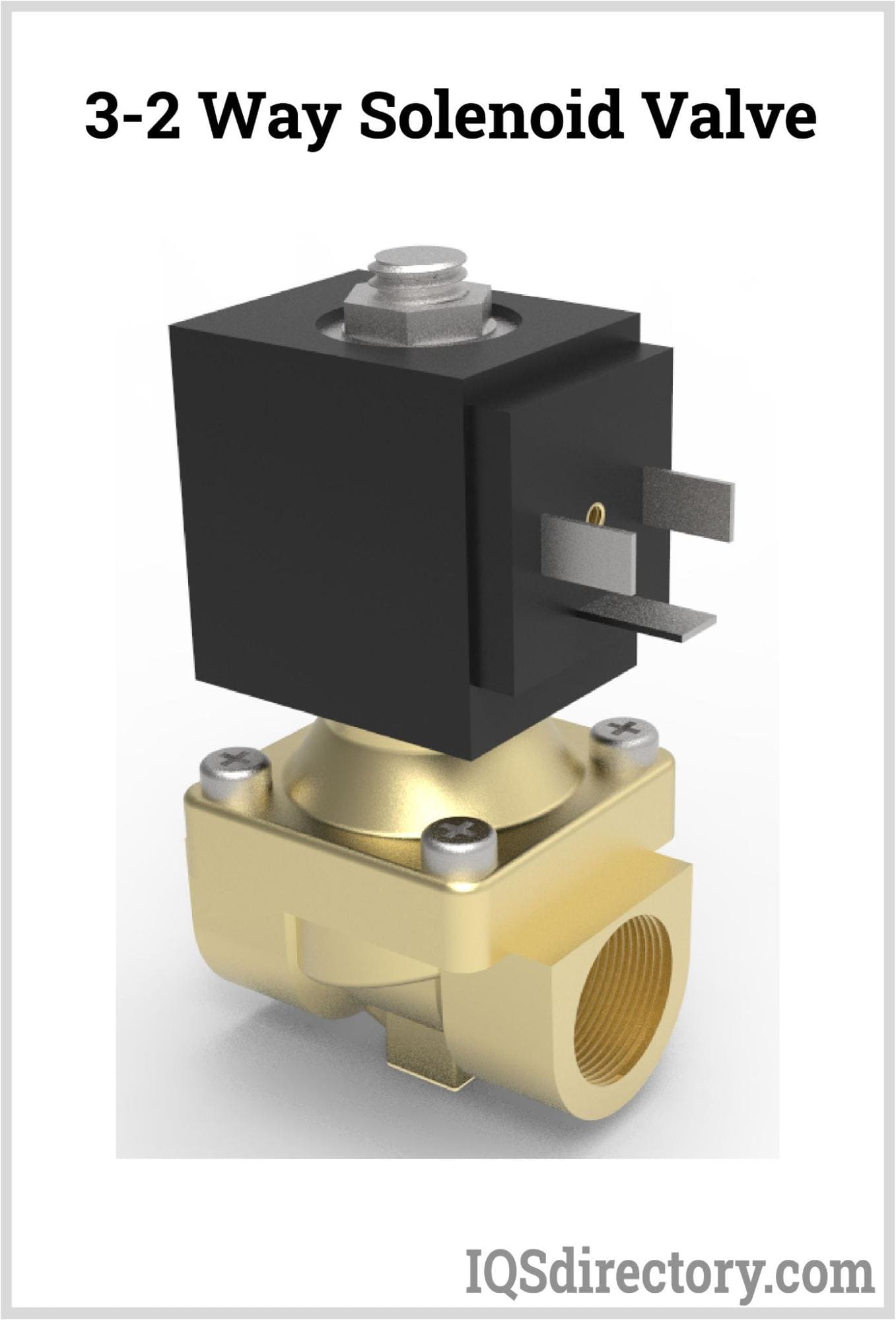

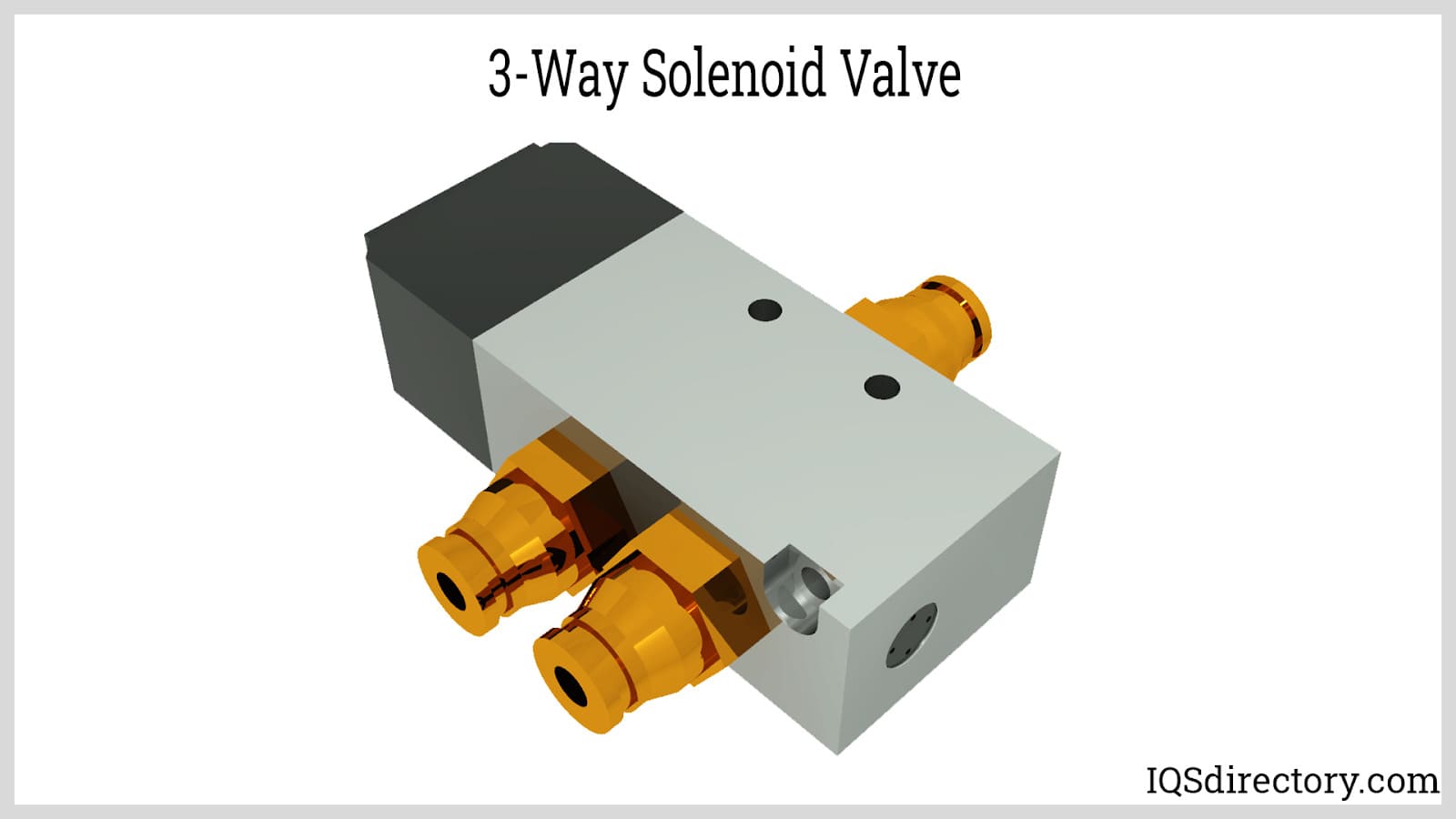

Direct Operated 3/2-Way Solenoid Valves

3/2-way solenoid valves with the direct operation have three ports and two switching states. However, only two ports are linked in each switching condition. This connection is because the valve flips states, and a new connection between the valve ports is made when the solenoid is activated. The medium can flow from the port on the right side to the top port when the device is de-energized. Likewise, the medium can go from the left port to the right port when it is activated. A 3/2-way valve that is generally closed is what this is.

2/2 Valves

These are electromechanically-actuated valves that regulate media flow between two ports using two (opened or closed) switching planes.

Symbols for Valves

The various switching states that the valve feature is described by its circuit function. Symbols are employed for a systematic representation. Two numbers are assigned to valves, such as a 2/2-way valve. The first number shows the number of connection ports. The quantity of switching states makes up the second number. A 2/2-way valve has two switching states and pipe connections (inlet and outlet) (open and closed).

The valve's state when de-energized is indicated by the designations normally closed (NC) or normally open (NO). Three ports and two switching states make up a 3/2-way valve. A different port is blocked in each switching state. It is possible to add more ports and switching states.

One square is drawn for each state of the valve. For example, a 2/2 valve, which has two possible states (open and closed), is symbolized by two neighboring squares. How a medium flows between the ports is displayed in each square. Arrows are used to denote which ports are connected and the direction of flow in this process. A "T" represents a closed port. A tiny actuator symbol is used on both sides to designate which square is active when the solenoid is electrically energized. To indicate that the left square is energized, a solenoid symbol is used on the left. For the resting state, a spring symbol is used on the right.

Applications of Solenoid Valves

Some businesses, like those in the medical and dental fields, require liquid or gas to execute a task. The equipment must be able to start and stop liquid or gas as necessary, regardless of the variations in the fields that use this sort of equipment. In this situation, solenoid valves are useful.

Advantages of Solenoid Valves

A solenoid valve's efficiency and safety features are some of its most important advantages. This valve can be used in a variety of applications. There are a variety of other advantages among solenoid valves, such as:

- Capable of remote operation and automation

- Includes inexpensive replaceable parts

- It can be used with both low and high temperatures.

- It can be installed horizontally or vertically.

- Matches various machinery parts and applications

- Low power consumption

Choosing the Proper 2-Way Solenoid Valve Manufacturer

To make sure you have the most beneficial outcome when purchasing 2-way solenoid valves from a 2-way solenoid valve manufacturer, it is important to compare at least 4 to 5 companies using our list of 2-way solenoid valve manufacturers. Each 2-way solenoid valve manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each 2-way solenoid valve business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple 2-way solenoid valve businesses with the same form.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services