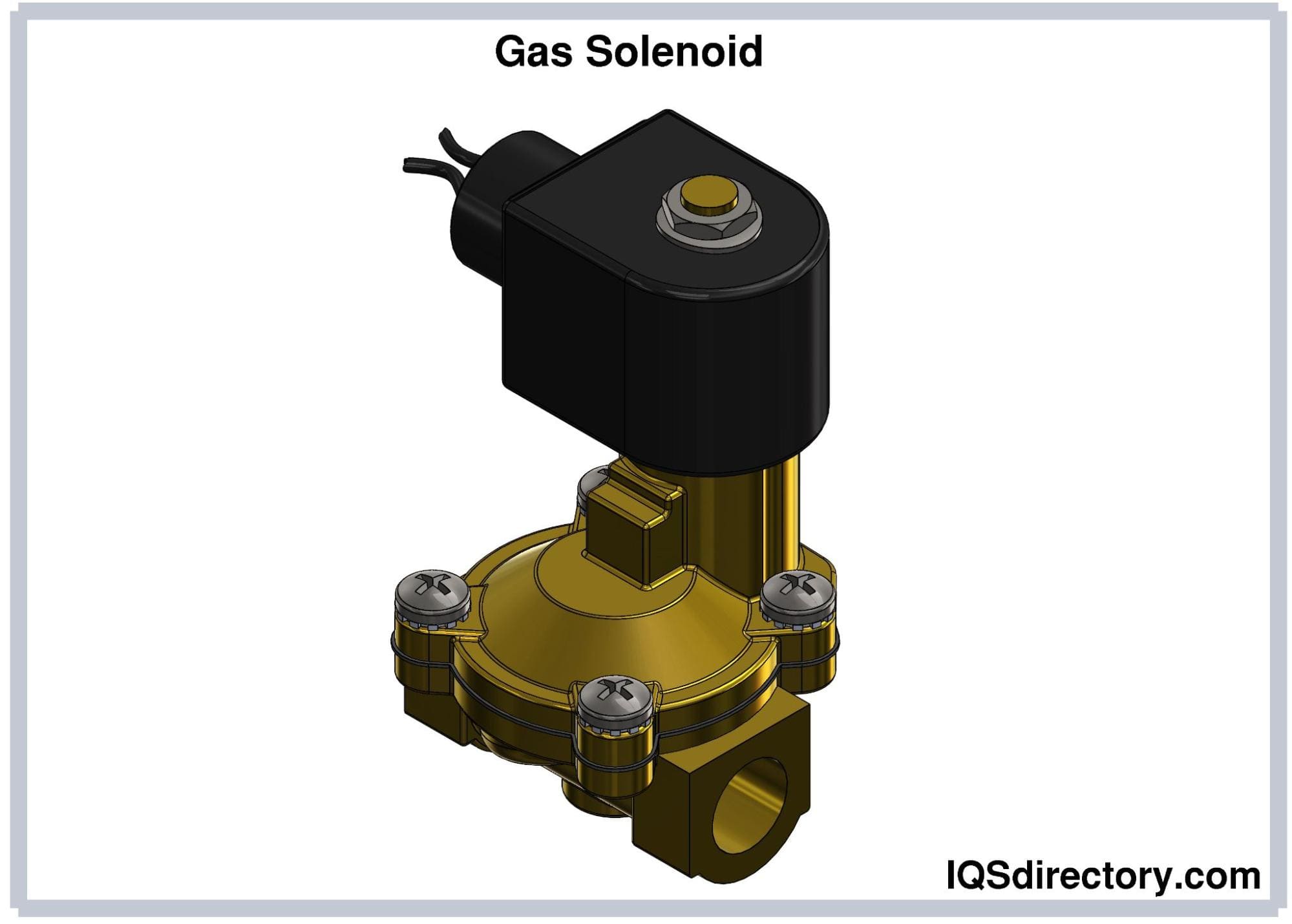

Gas solenoids are one of the most popular flow control valves for managing and controlling the flow of gaseous media. Like other valves, gas solenoid valves regulate the flow of gasses through tubes; however, unlike other valves, gas solenoid valves can be operated remotely. The most common actuation type for gas solenoid valves is pneumatic, but other options include electric and electro-pneumatic. Pneumatic power is cleaner and requires less maintenance than other actuation techniques, including hydraulic power. Read More…

Solenoid Solutions manufacturers custom direct-acting 2 and 3-way solenoid valves and multi-valve manifolds for OEMs in the medical, appliance, transportation, power generation and industrial equipment markets.

Our solenoid valves are all tested in house following very strict quality guidelines. We opened our doors in 1936 and ever since then we have been committed to bringing top of the line products and customer service that cannot be beat!

Lexair, Inc. stands at the forefront of innovation in the realm of solenoid valves. We are driven by a shared commitment to delivering unparalleled solutions to our customers. Our journey is defined by a passion for precision and a relentless pursuit of excellence in every aspect of solenoid valve design and manufacturing.

At Texas Industrial Remcor, Inc., we understand that the success of any industrial process hinges on the reliability and efficiency of its components. Therefore, our solenoid valves are meticulously engineered to deliver unparalleled performance, ensuring seamless operation in even the most demanding environments. We take pride in the precision and durability of our valves, a result of our...

At Hansen Technologies, we take immense pride in our extensive line of solenoid valves, crafted with precision and innovation. With a rich legacy of engineering excellence, we stand as a beacon of reliability in the realm of fluid control solutions.

More Gas Solenoid Valve Manufacturers

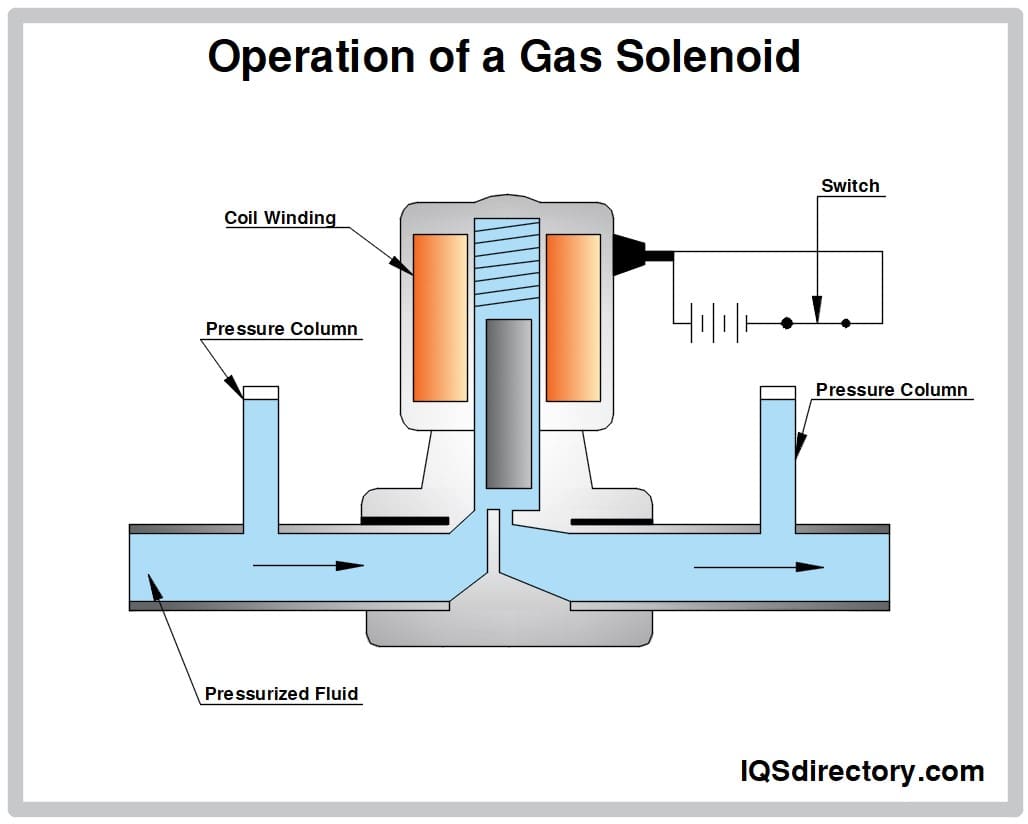

A Gas Solenoid Valve's Operation

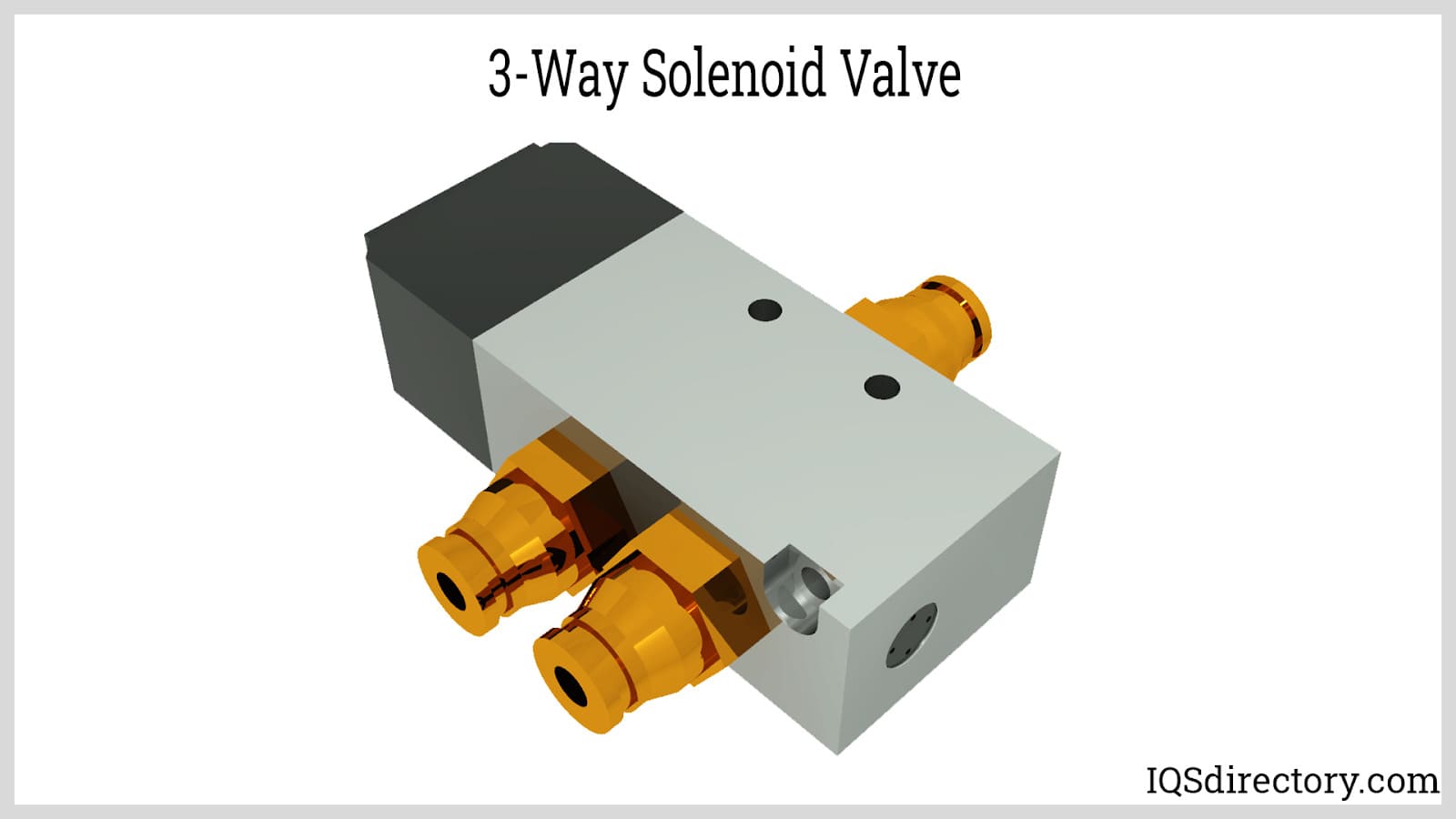

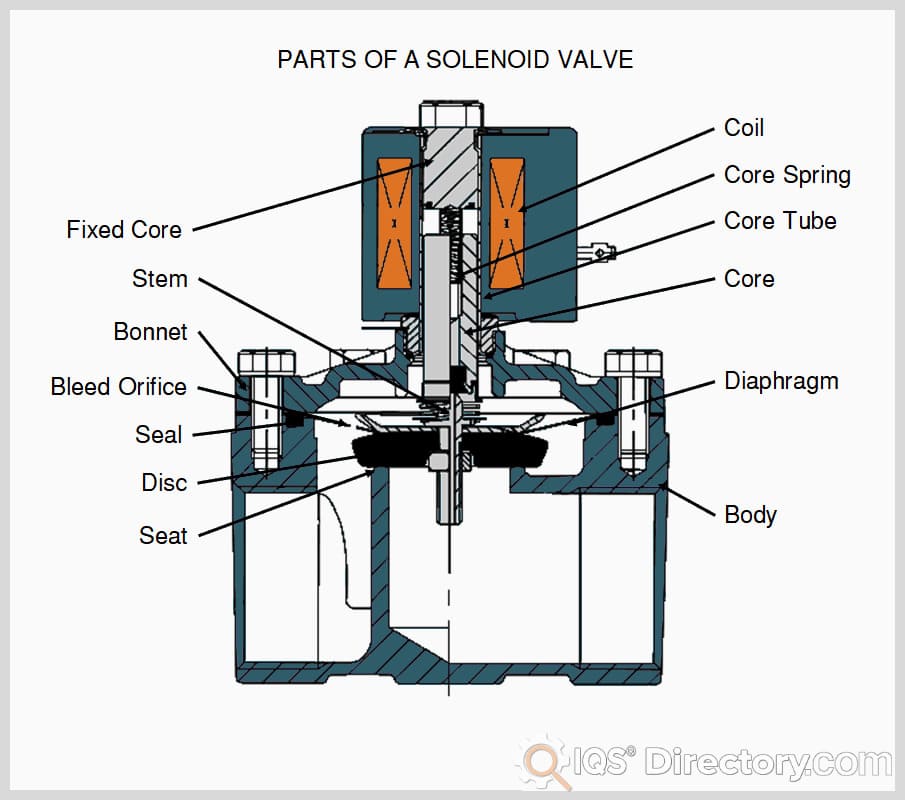

The electrical current that flows via the solenoid controls the valve. The valve's plunger descends, seals against orifices, and closes the valve when power is energized, creating a magnetic field. The flow of electricity through a solenoid valve stops the flow of a pressurized liquid or gas. Pulling the plunger and resetting it once the coil is de-energized is possible. The valve opens after the orifice is released from its seal. This process enables the gas or liquid under pressure to pass through the valve’s two-way solenoid valve controller.

Gas Solenoid Valve Types

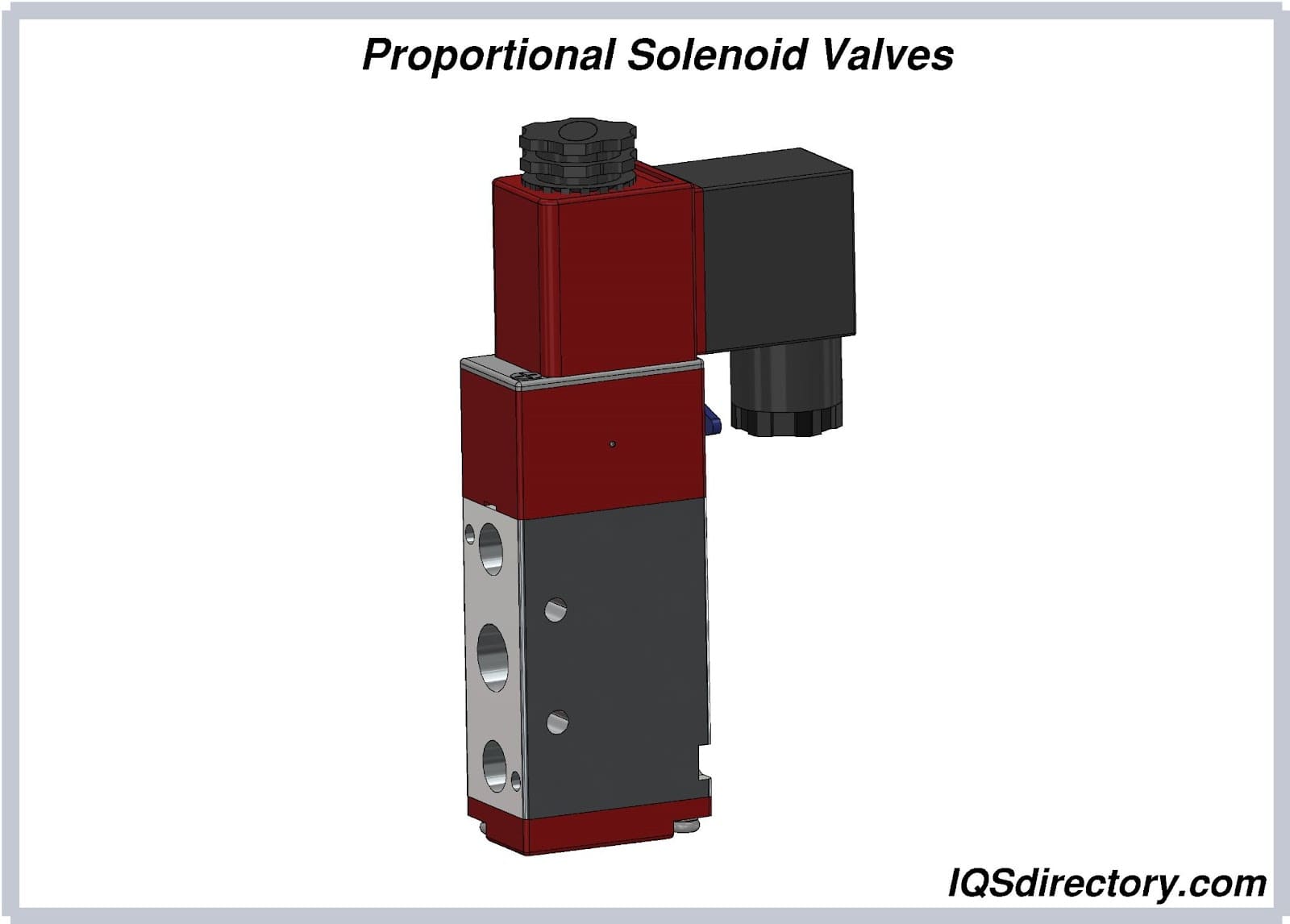

Gas solenoid valves are electromechanical devices that accurately control the flow of gasses using targeted electrical charges, sensor cues, or hysteresis. A solenoid is a magnetized coil that is actuated by electrical charges. Normally closed (NC) and normally open (NO) valves are both options for gas solenoid valves. An NC valve limits the airflow in a solenoid coil with a plunging pin or rod held inside the valve.

As long as the pin obstructs the airflow, the pressure inside the valve helps keep the valve closed. An electromagnetic charge is passed through the solenoid coil to activate it, raising the plunger out of the path and enabling gas to flow through the entire valve. The converse is true with NO valves; they stay open until the solenoid is engaged, halting the flow and applying pressure to keep the valve closed.

Direct-acting and pilot-operated valves are the two types of gas solenoid valves that are most frequently produced. The in-flow hole in the valve body or orifice is directly in touch with the plunger in direct-acting gas solenoid valves. The opening is opened and closed using this plunger to allow or restrict flow. Instead of requiring a plunger to operate, the pilot-operated gas solenoid valve uses a diaphragm to regulate the flow of gasses. In pilot-operated valves, a solenoid-operated vent is opened to let the pressure equalize, allowing gasses to pass through the valve's bigger chamber's diaphragm.

Solenoid Valve Applications

Due to the necessity of stopping the flow of gas in the system in the event of a gas leak, solenoid valves are utilized in most gas piping applications. One of the main purposes of an electronically controlled solenoid valve is to prevent the operator from using gas when there is a leak. One of its main advantages is a solenoid valve's ability to be installed in remote areas and controlled by basic electrical switches. Gas distribution, release, and shutoff are some of their most frequent applications.

The applications of gas solenoid valves are numerous. Gas solenoid valves have undergone design and engineering advancements that have made them safer and more effective. In addition, this valve can be modified to fit a range of applications and installed in several locations. The valve may also be opened and closed in less than a second, which is a huge benefit. An automated control system is essential for dangerous gasses and fluids that demand a lot of upkeep. A gas solenoid valve can be used in various procedures and tasks requiring:

- A minimal energy footprint

- Quick reaction time

- Capable of remote operation

- Able to be adapted to a wide range of machinery and applications

- Inexpensive replacement components

- Both DC and AC voltages are accessible

- Used in both high and low temperatures

- Protection against external leaks

- Installation may be vertical or horizontal

Benefits of Gas Solenoid Valves

Gas solenoid valves commonly regulate gaseous media such as air, nitrogen, argon, oxygen, hydrogen, liquid petroleum, and natural gas. Gas solenoid valves have a low control power. They are utilized in many different sectors, including the automotive, aerospace, oil and gas, commercial, agricultural, food processing, medical, semiconductor, and marine industries.

The more popular materials for gas solenoid valves are brass, PVC, polypropylene, polyethylene, PTFE, aluminum, copper, bronze, steel, cast iron, ductile iron, and stainless steel. Gas solenoid valves can also be produced from polymers, metallic elements, and alloys. Gas solenoid valves are available in various sizes and feature a compact design with fewer moving parts than most standard valves. Gas solenoid valves also provide the following:

- Quick and secure switching

- Lengthy useful lifetimes

- High reliability

- Good medium compatibility with the materials utilized

- Water sources

- Chromatography using gas

- Compressors

- Construction services

- Gas mixture control

- Cleaning and treating gray and dark water

- Firing mechanisms

- Drinking water purification

- Methods for putting out fires and protecting water mains

- Treatment of wastewater

- Control for gas and oil burners

- Regulating cleaning procedures

- Climate control, large heating systems

- Lubrication, dosage, and cooling

- Relief from pressure and drainage

- Tank and transportation facilities

- Tools for blood analysis

- Engineering of machinery and plants

Choosing the Proper Gas Solenoid Valve Manufacturer

To make sure you have the most beneficial outcome when purchasing gas solenoid valves from a gas solenoid valve manufacturer, it is important to compare at least 4 manufacturers using our list of gas solenoid valve companies. Each gas solenoid valve manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each gas solenoid valve company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple gas solenoid valve companies with the same form.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services