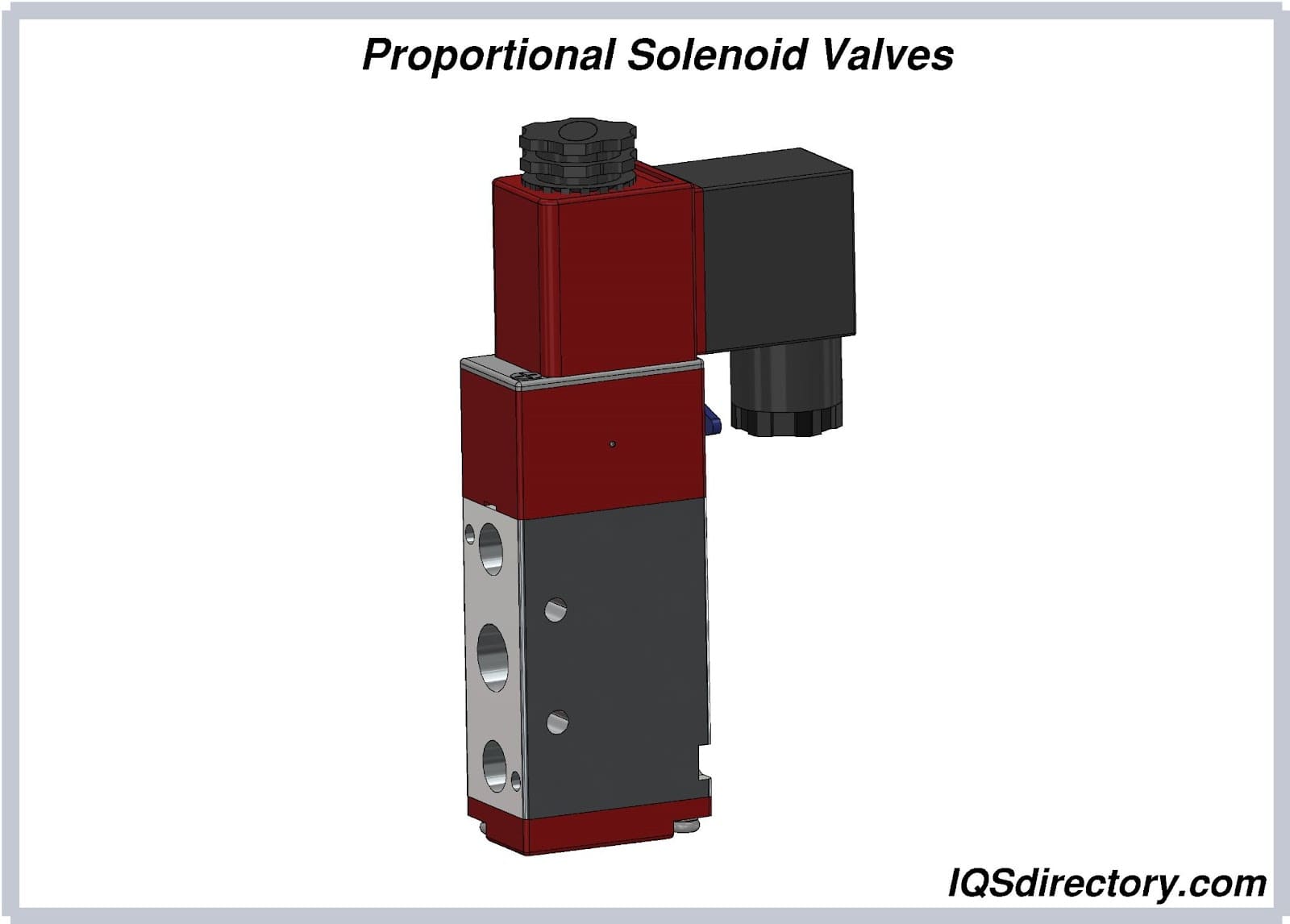

A proportional control valve alters the size of the flow path using a restrictor to control the fluid flow rate. The regulated flow rate then modifies system variables that impact a process: level, pressure, and temperature. Weight, thickness, humidity, density, pH, color, and viscosity are minor factors in this alteration. Read More…

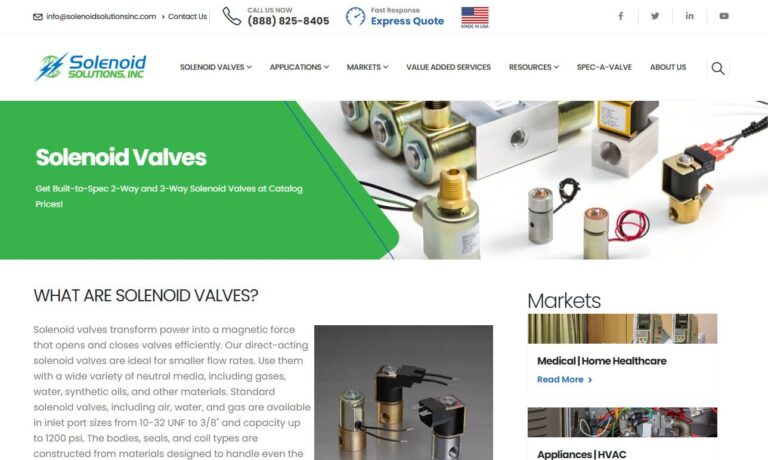

Solenoid Solutions manufacturers custom direct-acting 2 and 3-way solenoid valves and multi-valve manifolds for OEMs in the medical, appliance, transportation, power generation and industrial equipment markets.

Our solenoid valves are all tested in house following very strict quality guidelines. We opened our doors in 1936 and ever since then we have been committed to bringing top of the line products and customer service that cannot be beat!

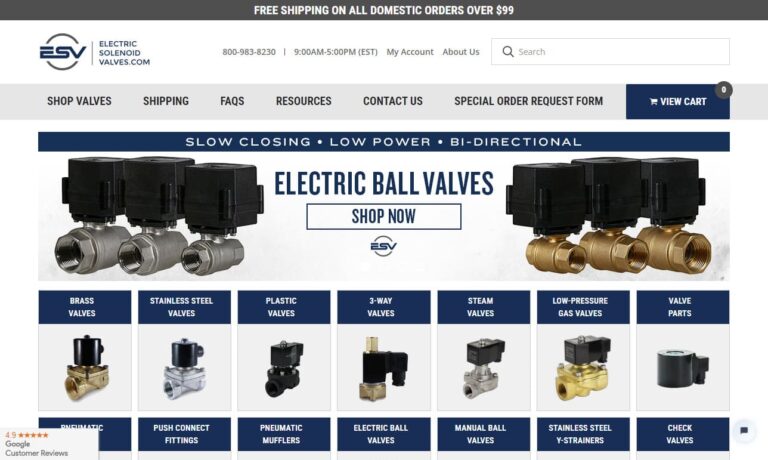

At Electric Solenoid Valves, we specialize in providing comprehensive solutions for solenoid valves, tailored to meet the diverse needs of our valued clientele. With expertise in fluid control systems, we have established ourselves as a trusted leader, known for our unwavering commitment to quality, innovation, and customer satisfaction. Our product offerings encompass a wide range of solenoid...

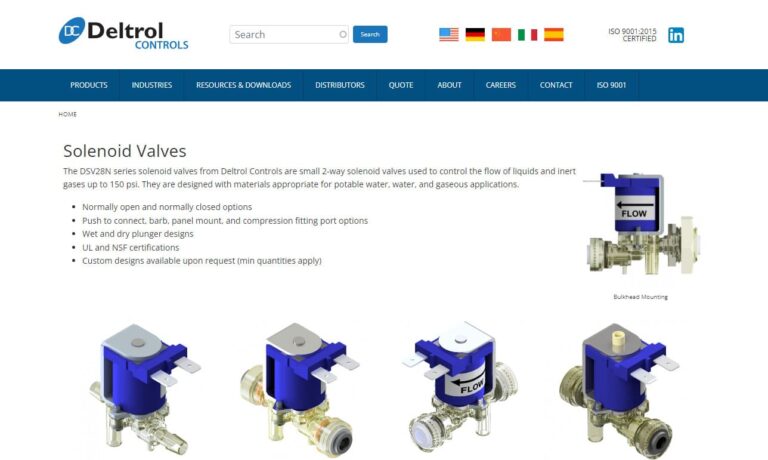

Deltrol Controls manufactures and designs a full line of stock and custom solenoids, electrical relays, dispensing valves, and custom switch assemblies. Customer satisfaction is our number one priority so we employ talented workers and stay up-to-date with the latest technology. Whatever your specific need is, Deltrol Controls has the solution. To receive a quote or more information please...

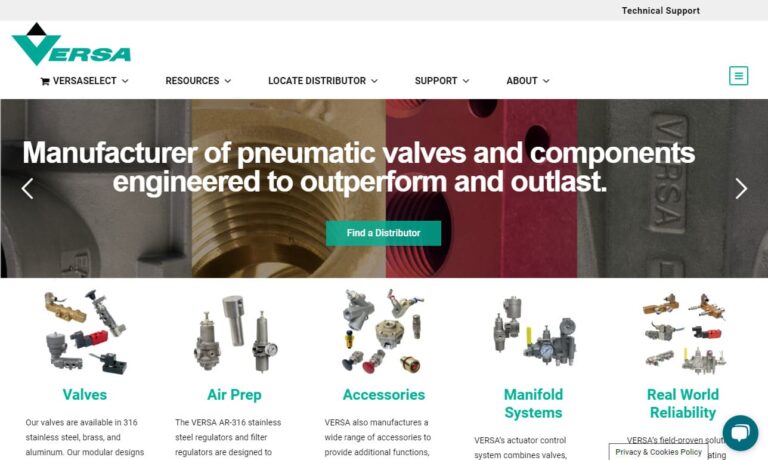

Versa® Products offers a wide range of pneumatic control valves, air valves and solenoid design. We have maintained our commitment to quality products and services since our company was established in 1949. We are a solenoid valve manufacturer, offering solenoids in brass and stainless steel.

More Proportional Solenoid Valve Manufacturers

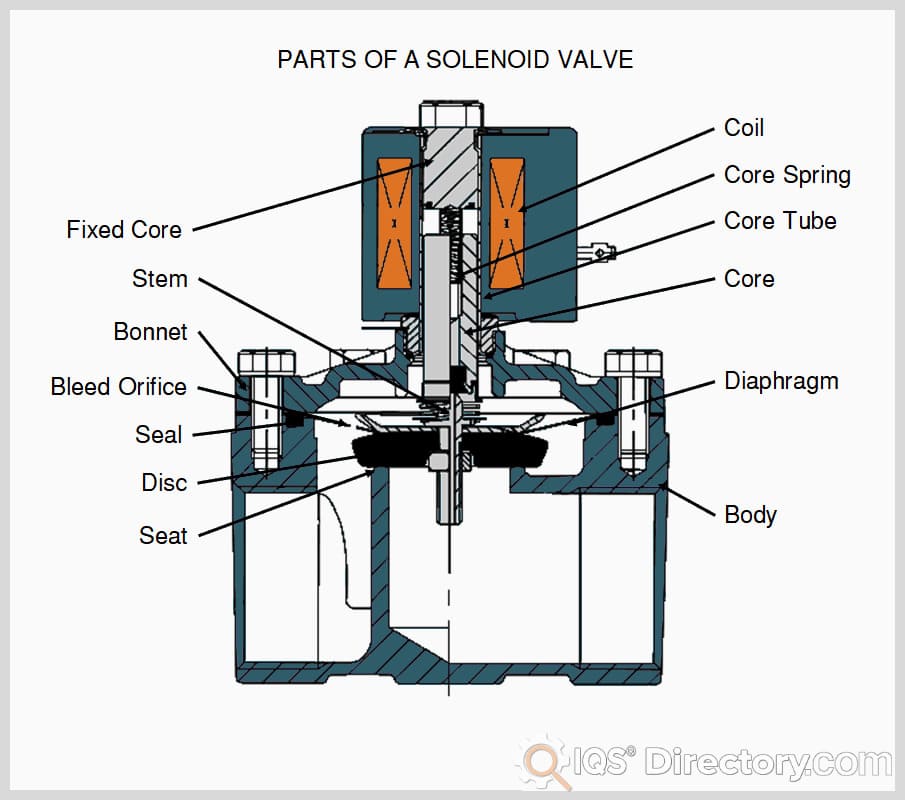

A signal from an actuator controls the restrictor in an automatic control valve. For example, a solenoid is used as an actuator for a proportional control solenoid valve, which allows for variable valve location. While a direct-operated solenoid valve can work through various valve settings, a direct-operated 2-way standard proportional solenoid valve behaves similarly. The latter, however, only offers two switching states on and off. The restrictor of a direct-operated proportional solenoid valve is the plunger.

Operating Principle

The plunger might theoretically be proportionally controlled with varying DC voltage. But in reality, static friction on the plunger's guiding points reduces the valve's sensitivity, leading to more pronounced hysteresis effects (the phenomenon in which the value of a physical modification to a property takes longer than changes to the cause of it. To reduce static friction, the regular intake signal can be changed into a pulse-width modulated voltage signal (PWM).

PWM is a common method for allowing the control of the power supplied to electrical equipment. The average voltage (and current) provided to the solenoid is managed by quickly flipping the power switch on and off. This type of control causes the plunger to oscillate extremely quickly but with a small amplitude. In addition, the oscillation maintains the plunger's consistent sliding friction by putting it in a balanced position. As a result, the oscillation motion of the plunger has no impact on how the fluid behaves during flow.

The overall power provided to the solenoid increases while the switch is on for a longer time compared to when it is off. The ratio of the on-time, t1, to the cycle duration, T, is called the duty cycle. As a result of the power being off most of the time, a low-duty cycle equates to low power. In terms of duty cycle, 100 percent corresponds to full-on.

In a typically closed solenoid control valve, the spring forces the plunger downward to a fully closed position when no current is provided to the coil. As a result, the valve is kept closed. The plunger is forced upward against the return spring by a magnetic field created when current is applied to the coil. Power is fully delivered to the solenoid, and the valve is kept open at a 100 percent duty cycle. The flow via the valve is adjusted proportionally by duty cycles between 0 and 100 percent. For instance, a solenoid with a 50% duty cycle will move the spring and plunger to 50% of its operating range.

Choosing a Proportional Solenoid Valve

Compared to on/off valves, selecting the proper valve size is far more crucial in continuous flow applications. At a very small opening and a high orifice setting, the valve can achieve full flow (stroke). The remaining stroke is ineffective and degrades the valve's ability to resolve problems and maintain general control. On the other side, if the orifice size is too small, the valve won't be able to handle the total flow rate. It is advised that the pressure drop across the valve be roughly 30% of the system's overall pressure drop.

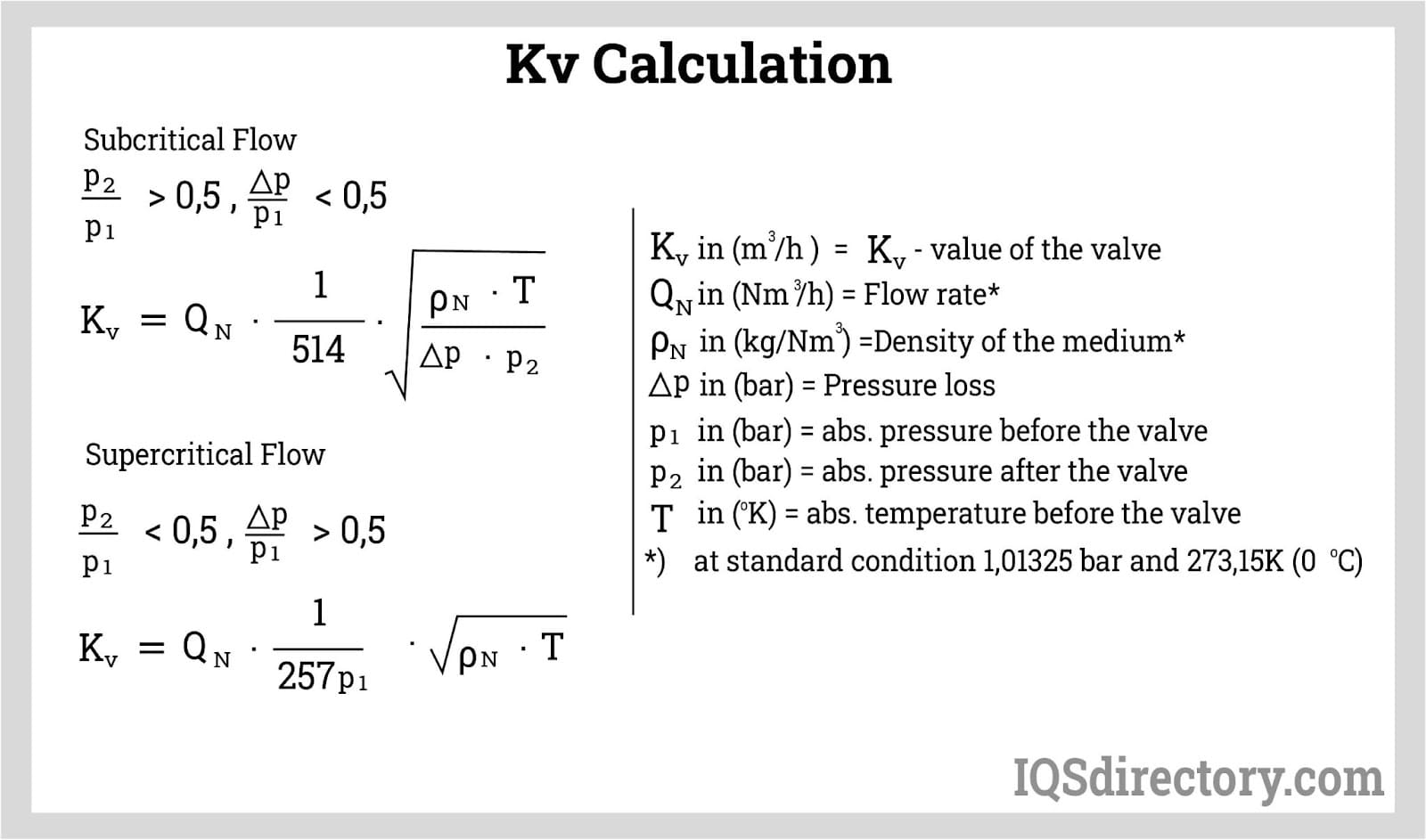

For the control to function correctly and precisely, solenoid control valves must be set up and chosen in accordance with their unique purpose. The kV value (expressed in m3/h) and the pressure range of the application are the two most crucial factors to consider when choosing a solenoid control valve. The valve can withstand higher pressures if its orifice is smaller or its coil is stronger. The image below shows sizing formulas used to determine the highest kV value required.

Kv calculation in Figure 2: where:

- QN= Normal Flow rate [m3/hour]

- Kv = Hydraulic factor

- T = Inlet gas temperature [K]

- p1 = Inlet Pressure [bar]

- p2 = Outlet Pressure [bar]

- dp = Pressure differential [bar]

- SG = Specific Gravity (Air = 1)

A corresponding appropriate valve type and critical orifice can be identified based on the computed kV value and the anticipated application's pressure range. Note that the valve's kVs should ideally be about 10% higher than the application's kV.

Maximum operating pressure, media (fluid), power consumption, material compatibility, response time, media temperature, operating voltage, and port connection are a few other selection variables to consider.

Typical Applications of Solenoid Valves

Following are a few typical uses for proportional solenoid control valves.

Burner/Flame Control: In a burner control system, two gasses must be kept in the correct ratio. The flame necessary for the specific process determines the ratio of combustion gas to oxidant gas, such as air or oxygen.

Level Control with Pressurization (Flow Pressure Control): One sort of level control is the regulation of atmospheric pressure. A PID controller uses two solenoid control valves to supply enough air or nitrogen so that the fluid is constantly under the same pressure.

Mixing Cold and Warm Water: The combined water temperature is measured with a Pt100 temperature sensor. By appropriately operating two solenoid control valves, the temperature controller raises this temperature to the specified reference value.

Temperature Control: A solenoid control valve can adjust the cold water supply to a heat exchanger in line with the observed process water temperature. If this number exceeds the reference value, more cold water is needed. Conversely, less cooling is needed if it is lower than the reference value.

Flow Control: Direct flow control can be achieved by using a solenoid control valve as a control valve.

Choosing the Correct Proportional Solenoid Valve Supplier

To make sure you have the most productive outcome when purchasing proportional solenoid valves from a proportional solenoid valve company, it is important to compare at least 4 suppliers using our proportional solenoid valve directory. Each proportional solenoid valve supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each proportional solenoid valve business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple proportional solenoid valve companies using the same message.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services